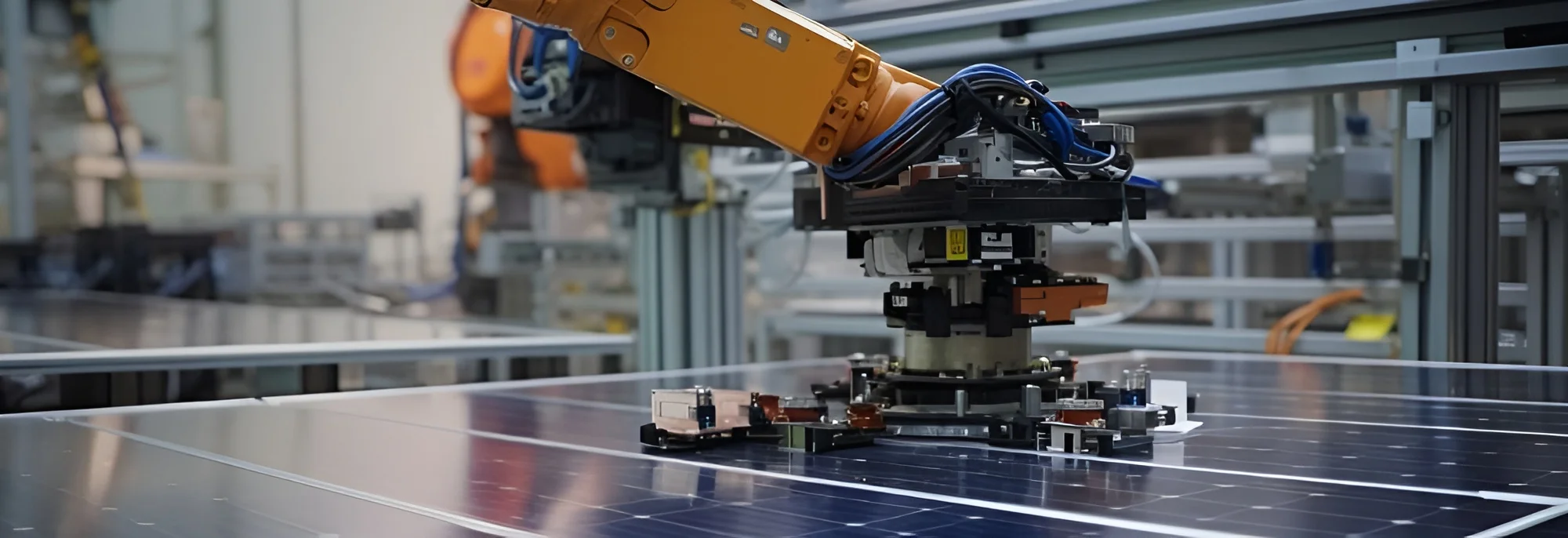

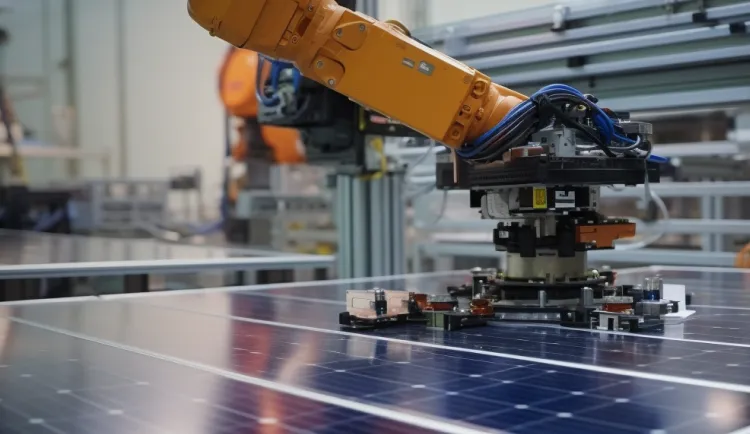

Intelligent production

The manufacturing management platform, capable of real-time monitoring.analysis and diagnosis, minimizes the interference of production, ensuring product quality and cost efficiency.

Intelligent manufacturing

The manufacture procedure mass data analysis system, based on intelligent analysis of the data collected in the manufacturing process, applies the results to control of equipment, manufacture procedure and yield, ensuring efficient and stable operation of all manufacturing equipment in the production line.

Meanwhile, utilizing the results of intelligent analysis,the factory can shorten the yield learning curve and the time required for initiating mass production of new technologies and products, motivating rapid release and expansion of potential production capacity in the period of strong market demand to meet customer needs.