Total Quality Management System

Aware that quality is at the core of product competitiveness, the company subiects research and development, production and service to total quality manaeement system, improves product quality through a sound quality management system. and exands the market with hieh-qualty products and services.

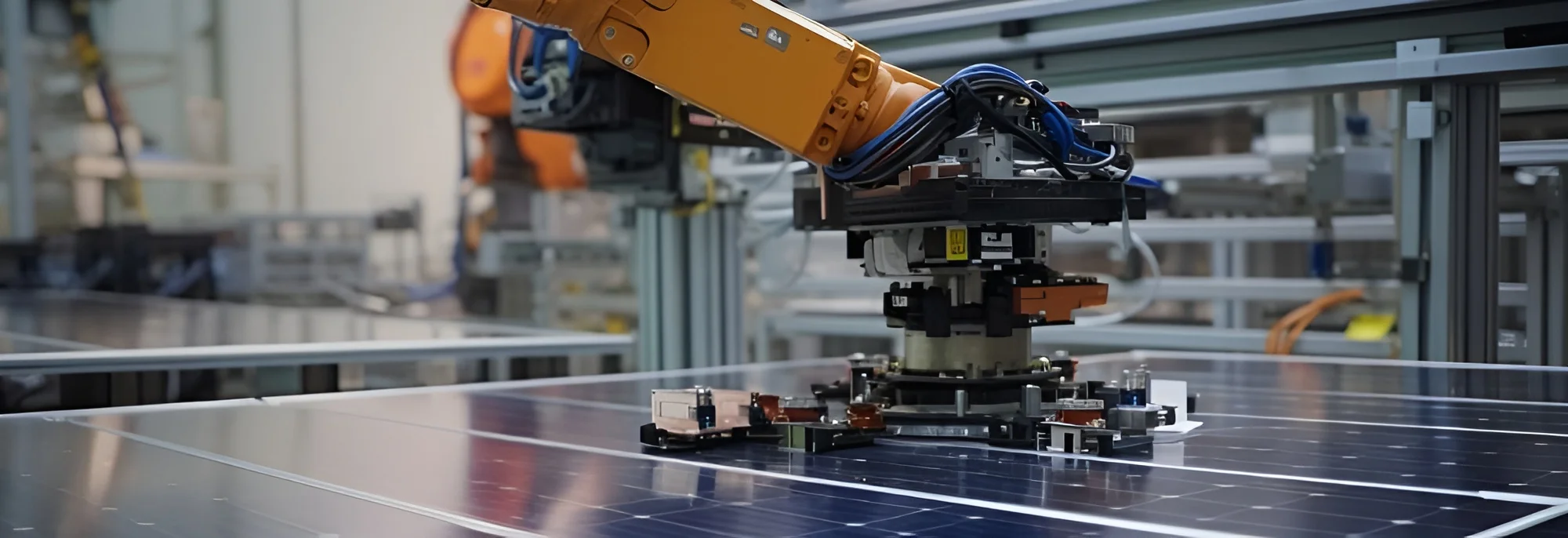

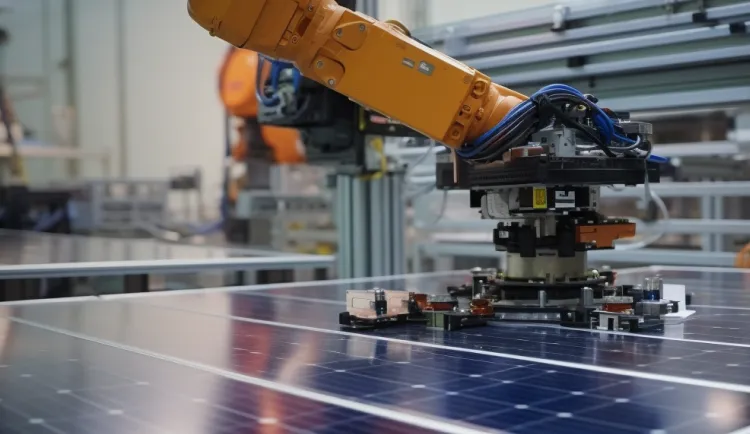

Awaken Solar, which makes production line more inteligent, efficient, integrated and modular as design purpose, adopts intelligent core technologies,including inovance technology and other industrial control software, driving the intelectualization of quality inspection,data statistics, cause analysis, and diagnosis in the production process.